-

Enhancing Metal Surface Treatment with Ultrasonic Cleaning: A Comprehensive Overview

Enhancing Metal Surface Treatment with Ultrasonic Cleaning: A Comprehensive Overview

Ultrasonic cleaning has emerged as a vital technology in various industrial applications, particularly in metal surface treatment. The process uses high-frequency ultrasonic waves to remove contaminants from metal surfaces, significantly improving the eff

-

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

Ultrasonic cleaner transducers (also called piezoelectric vibrators or "振子" in Chinese) require specialized adhesives to ensure optimal performance an……

-

How to Remove Rust with an Ultrasonic Cleaner: The Ultimate Guide

How to Remove Rust with an Ultrasonic Cleaner: The Ultimate Guide

Rust removal is one of the most challenging cleaning tasks, butultrasonic cleanerscan make it surprisingly efficient and thorough. This guide will walk you through the science behind ultrasonic rust removal, step-by-step instructions, and expert tips to r

-

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

Proper rust prevention after ultrasonic cleaning is crucial for metal parts longevity. This guide covers industrial-grade passivation techniques, eco-friendly sealants, and cutting-edge nano-coatings to create durable anti-corrosion barriers while maintai

-

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

1. Why Use Ultrasonic Cleaners in Automotive Repair? Ultrasonic cleaning is a game-changer for auto shops and DIY mechanics because: Deep Cleaning: Removes 90%+ of contaminants (oil, carbon, rust) from complex parts like fuel injectors.

-

How to Use Ultrasonic Cleaners for Auto Repair: A Complete Guide to Cleaning Car Parts

How to Use Ultrasonic Cleaners for Auto Repair: A Complete Guide to Cleaning Car Parts

1. Why Use Ultrasonic Cleaners in Auto Repair? Ultrasonic cleaning is10x fasterthan manual scrubbing (industry tests show 90%+ contaminant removal in 15 minutes). Benefits include: Deep cleaningof intricate parts (fuel injectors, turbo f

-

What Type of Ultrasonic Cleaning Machine Is Best? A Professional Perspective

What Type of Ultrasonic Cleaning Machine Is Best? A Professional Perspective

Ultrasonic cleaning machines are versatile tools that leverage high-frequency sound waves to create cavitation bubbles, which effectively remove contaminants from surfaces. These machines are widely used across various industries due to their precision, e

-

Understanding the Industry Classification of Ultrasonic Cleaning Machines

Understanding the Industry Classification of Ultrasonic Cleaning Machines

1. Introduction Ultrasonic cleaning machines are innovative tools that leverage high-frequency sound waves to clean objects with precision and efficiency. These machines are integral to multiple industries due to their ability to remove contaminants fr

-

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

Ultrasonic cleaning is a powerful and efficient cleaning technique that uses high-frequency sound waves (typically 20-40 kHz) to create microscopic bubbles in a cleaning liquid. These bubbles form and collapse rapidly, a process known as cavitation, which

-

Maximizing Cleaning Efficiency: Techniques for Using Ultrasonic Cleaners

Maximizing Cleaning Efficiency: Techniques for Using Ultrasonic Cleaners

Introduction Ultrasonic cleaning has emerged as an invaluable method in various industries for its efficiency and effectiveness in removing contaminants. The process utilizes high-frequency sound waves to create microscopic bubbles in a liquid cleaning

-

Ultrasonic Cleaners in Aerospace Manufacturing: Unmatched Cleaning Efficacy

Ultrasonic Cleaners in Aerospace Manufacturing: Unmatched Cleaning Efficacy

Introduction In the aerospace manufacturing sector, maintaining high standards of cleanliness is paramount. The intricate components used in aircraft and spacecraft are subject to stringent regulations and must meet rigorous quality control standards t

-

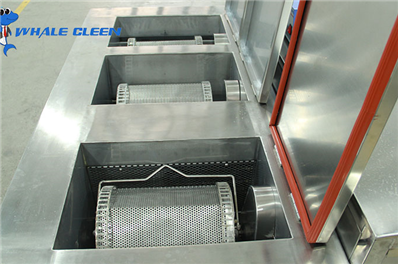

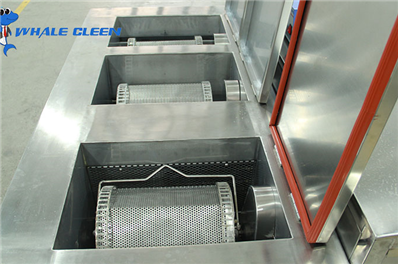

Ultrasonic Cleaning Machines: A Revolutionary Tool in Metalworking

Ultrasonic Cleaning Machines: A Revolutionary Tool in Metalworking

Metalworking is a key pillar of numerous industries, including automotive, aerospace, manufacturing, and engineering. Within this domain, maintaining the cleanliness of metal parts is essential to ensure product quality, longevity, and functional efficien

Enhancing Metal Surface Treatment with Ultrasonic Cleaning: A Comprehensive Overview

Enhancing Metal Surface Treatment with Ultrasonic Cleaning: A Comprehensive Overview

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

What Adhesive is Used for Ultrasonic Cleaner Transducers? The Complete Bonding Guide

How to Remove Rust with an Ultrasonic Cleaner: The Ultimate Guide

How to Remove Rust with an Ultrasonic Cleaner: The Ultimate Guide

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

How to Prevent Rust After Ultrasonic Cleaning: 5 Scientifically Proven Protection Methods

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

How to Use Ultrasonic Cleaners for Automotive Repair? A Step-by-Step Guide

How to Use Ultrasonic Cleaners for Auto Repair: A Complete Guide to Cleaning Car Parts

How to Use Ultrasonic Cleaners for Auto Repair: A Complete Guide to Cleaning Car Parts

What Type of Ultrasonic Cleaning Machine Is Best? A Professional Perspective

What Type of Ultrasonic Cleaning Machine Is Best? A Professional Perspective

Understanding the Industry Classification of Ultrasonic Cleaning Machines

Understanding the Industry Classification of Ultrasonic Cleaning Machines

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

What Should Not Be Cleaned with an Ultrasonic Cleaner: Key Considerations and Restrictions

Maximizing Cleaning Efficiency: Techniques for Using Ultrasonic Cleaners

Maximizing Cleaning Efficiency: Techniques for Using Ultrasonic Cleaners

Ultrasonic Cleaners in Aerospace Manufacturing: Unmatched Cleaning Efficacy

Ultrasonic Cleaners in Aerospace Manufacturing: Unmatched Cleaning Efficacy

Ultrasonic Cleaning Machines: A Revolutionary Tool in Metalworking

Ultrasonic Cleaning Machines: A Revolutionary Tool in Metalworking